Rigid gantries

These are the building’s main support. They are made from reinforced double-T girders and columns of variable section.

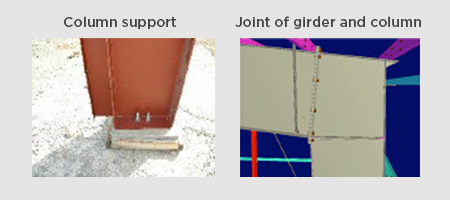

The girder is coupled to the column by means of bolted joints. These joints give the gantry a rigidity capable of absorbing horizontal stress while helping to support vertical loads.

When the gantry is not rigid, as is the case in systems with posts and lattices, they have to be anchored to horizontal supports .

-

Column supports

The columns of the rigid gantry rest on base plaques, joined to the foundations by means of anchor bolts embedded in the footing.

The connection of the column base to the foundation is considered to be a ball-and-socket joint, so only vertical and horizontal reactions are transmitted but not moments; accordingly, the foundation design is much simpler than in other kinds of constructions. Only in special cases where the dimensions of the overhead crane are large would it be necessary to embed the column bases.

-

Design loads

Apart from normal loads such as the weight of the building itself, snow loads and wind, etc., buildings can be calculated for hoist supports, overhead cranes and future enlargements supported already-existing columns.

-

Calculation

Calculation of the structure is carried out by means of advanced software, achieving total accuracy and technical rigor in all the data that has to be taken into account for each use.

-

Separation between gantries

Within our standard dimensions, gantries are situated at a distance between axes of 8.00 m. and 11.00 m., although on request we can position them at other distances.

-

Pendiente de tejado

We usually have two standard slopes, the first with 10% (1/10) and the second with 5%.

On request, we are prepared for any other that is requested.

Extensions of surface areas

Quite often, the requirements for which an industrial unit has been planned increase, making it necessary to enlarge it.

When the construction is in civil engineering, the cost of the longitudinal extensions is high, and practically none of the demolition materials can be recovered. With this same system, sideways extensions (to increase the width of the industrial unit) are practically impossible.

With the TEKTON system, the problem of longitudinal extensions is solved by gantries, and for sideways extensions, the gantries can be equipped with holes in the joint between beam and column with the purpose of coupling future semi-gantries to them. Sideways extensions can be single or multiple as they are made up of one or several semi-gantries. In these extensions, all materials are recoverable, involving very low costs.

-

Construction combinations

A large number of construction combinations can be included within a surface area, of different widths and/or heights, both in one same model, with or without intermediate supports.

-

Appearance

Regardless of the quality of the materials used, the structural system based on solid gantries, variable section, low gradient, etc., fulfills another function which is increasingly importanct: appearance

Recoverability of materials

The gantries are made up of several sections joined to each other by high-resistance bolts without any component needing to be welded in assembly. This attribute extends to the other components of the building, making it possible to fully recover them and, if the need arises, to transfer them to a new location.